Drawings available under tab: Downloads.

All lenses are 100% Rohs compliant and fulfill all requirements under REACH.

Application Note

This application note contains all necessary information for the user of these lenses. Includes information on temperature stability, manufacturing and quality procedures, packaging and ordering information.

Lens-Laser layout

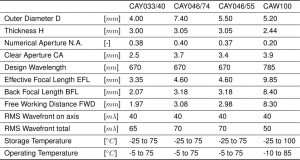

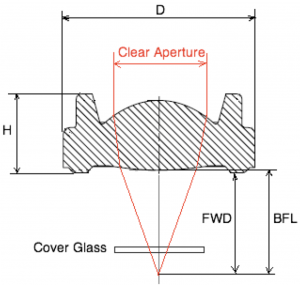

The design with its aspherical corrections is optimized for 670 nm, but the lenses can be used in a wide variety of wavelengths from 400 to 950 nm. Within this whole spectrum the aberrations will be lower than the specified limit. Take care that the BFL changes when the lens is used at another wavelength. Consult us for the right value.

The laser cover glass taken into account in the design is 0.25 mm BK7, distance 0.55 mm from the laser. In case no cover glass is used, the BFL will change accordingly. As long as this is taken into account when focusing the lens, this will not harm the function of the lens. Consult us in case of doubt.

The diameter D is the mechanical outside diameter of the lens and should be used for axial reference of the lens toward the laser beam. Please note that the lens type CAY033/40 has a gate protrusion, outside this diameter D.

The design in Zemax (as .ZMX file) and the drawing for opto-mechanical in-design can be made available on request.

The stated focal length is a nominal value and delivered parts typically will show a variation of the focal length of ± 50 micrometer.

Environmental specifications

Lenses have been tested under various conditions and been found to be stable under storage conditions in general from -25 C to 90 C. Tests have been done under IEC 60068-2. Apart from abrasion resistance all tests are passed. For abrasion resistance the nature of the plastic poses limitations: this is a relatively soft material and should be cleaned with non-mechanical means, like cleaning by blowing antistatic air or in an ultra-sonic fluid bath.

Temperature Behavior

Because our lenses are manufactured from plastic material, they show different material characteristics as compared to lenses made from glass. One of these characteristics is the change of the index of refraction with the temperature. This coefficient is called dn/dT and has a value of -1×10-4 (or -0,0001) /°C. Which means that an n=1.531 would decrease to n=1.530 with a temperature increase of 10 °C.

To achieve precision, this effect must be taken into consideration when doing a design with plastic optics. The designer must make sure that the spot size is still within specification at lowest and highest use temperature.

It helps when the index used for the design is corrected for this effect and has the value of the center temperature of the use temperature window. E.g. in an application which is used from 10-60 °C, recalculate the value of n to 35 °C.

Refocusing after temperature change also takes away the problem. When plastic lenses are used in an Autofocus system the problem virtually disappears.

The maximum storage temperature is the temperature until which all changes in the material are fully reversible: essentially the characteristics of the lens fully return to the original, when temperature is restored to original. This means that the storage temperature range can be considered the as the maximum use temperature range, as long as the index change influence is verified.

Manufacturing and Quality monitoring

The lenses are manufactured under clean room conditions on precision injection molding machines. Also necessary secondary operations and packaging is done under clean room conditions, class 100k. Materials used are optical plastics of renowned manufacturers, guaranteeing the index of refraction of the material within strict tolerances.

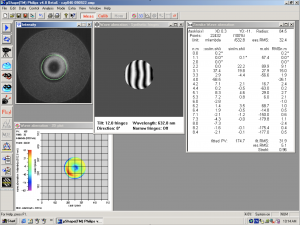

Parts are manufactured in large series of 20.000 lenses minimum and the quality is monitored with Statistical Process Control. Under SPC are: EFL and RMS wave front aberrations. This will guarantee the quality of the spot shape as well as the size.

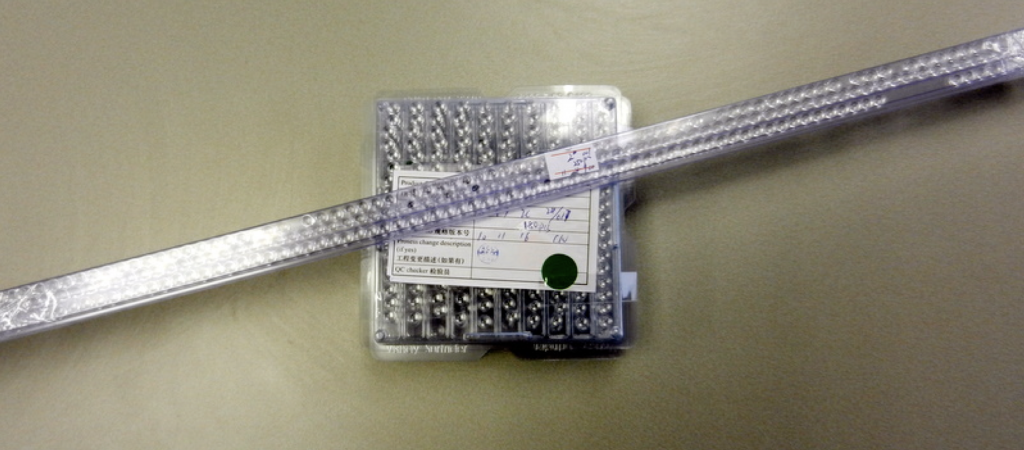

Packaging and Shipment/Order Volumes

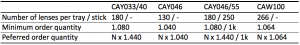

For transport package Penta uses tray package for most lenstypes. For CAY046/55 also a stick package is available. The number of lenses in the smallest packaging unit is given in the table below. So orders have to be issued in multiples thereof, with an absolute minimum of approx. 1.050 pcs. Deviation from the standard volumes is possible of course, but additional cost may occur.

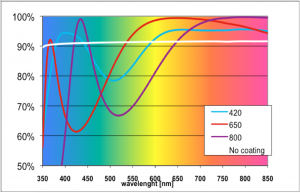

Anti-Reflex Coating

As an option the lenses can be coated to minimize reflections on the surfaces: the so-called AR-coating. This coating is a stack of dielectric layers on the surface of the lens. The working of the coating is wavelength dependent, so we specify the coating at a certain wavelength. Coatings are available for 420, 650 and 800 nm design wavelength. Note from the below diagram that the coating has a wider wavelength range use, depending the type of coating and the wavelength range.